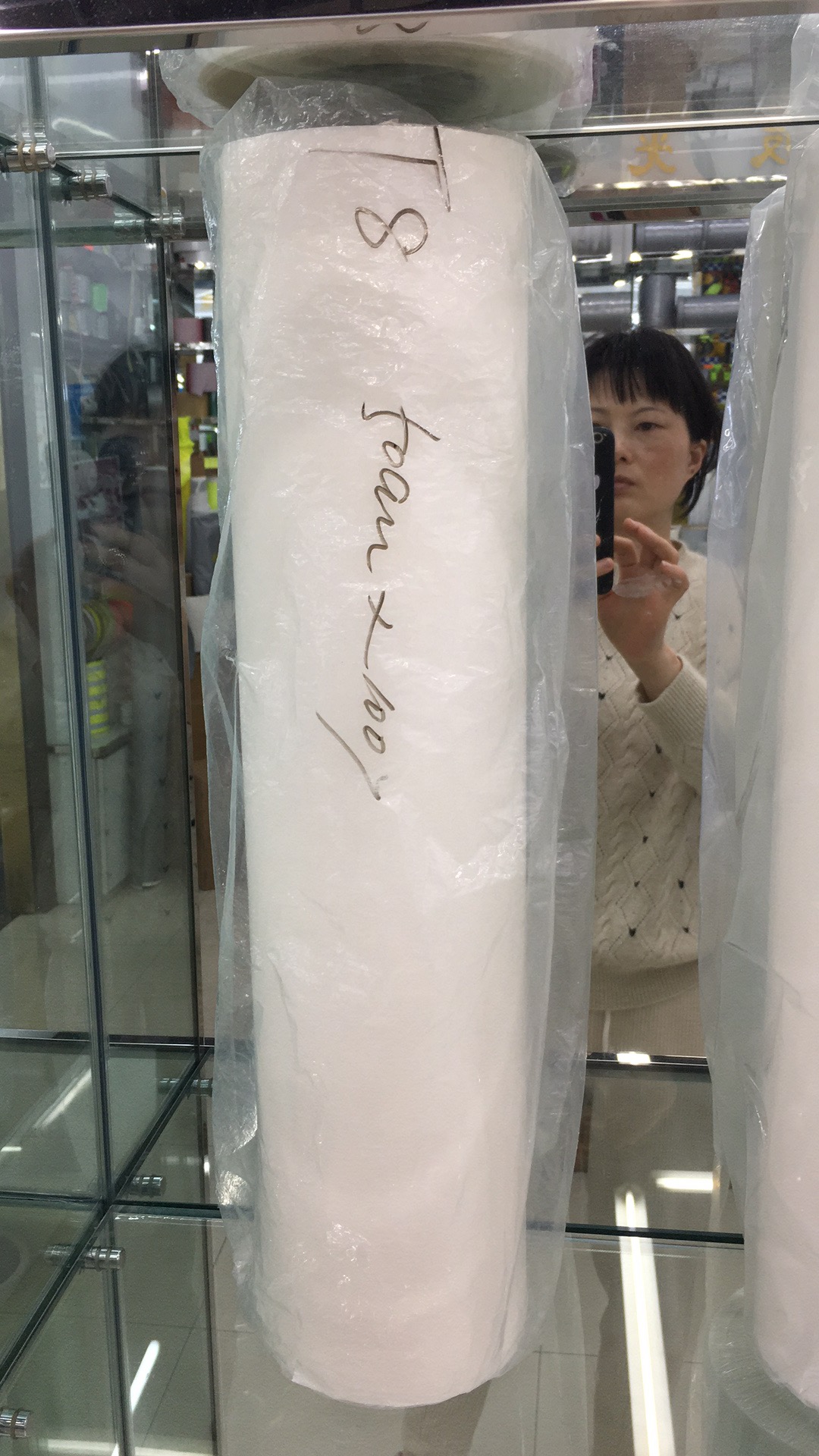

Explore the unique charm of TPU hot melt adhesive film

In-depth discussion of the wide application of TPU hot melt adhesive film in the field of clothing manufacturing and its significant advantages. Learn how this high-tech material revolutionizes traditional sewing and gluing processes, making clothes not only more beautiful and durable, but also more functional. Whether it is high-end fashion or functional clothing, are inseparable from this magical adhesive.

From high-end custom dresses to daily wear work clothes, to outdoor sports equipment, TPU hot melt adhesive film has become an indispensable part with its unique physical properties and efficient processing methods. It can not only replace the traditional needle and thread to complete the seamless splicing task, but also increase the tightness and firmness between the fabrics, thereby extending the service life and improving the overall texture.

The science behind superior performance

Discover why TPU hot melt adhesive film can achieve such excellent waterproof effect and super adhesion. A detailed analysis of its molecular structure and chemical composition reveals the technical mysteries behind these properties. By comparing other types of film, TPU shows the superior performance in terms of stability, flexibility, etc.

As a high molecular polymer, TPU is formed by reacting polyol (Polyol) and isocyanate (Isocyanate) to form a network cross-linked structure with elasticity. When heated to a certain temperature, it can quickly melt and form a strong chemical bond with the contact surface; the film after cooling and curing shows excellent hydrolysis resistance and mechanical strength, even after repeated washing is not easy to fall off or deformation.

Green security

Emphasize the core value of TPU hot melt adhesive film as an environmentally friendly product-non-toxic substances release, environmentally friendly and no threat to human health. Introduce the strict standards followed in the production process and the relevant certification marks obtained, so that consumers can rest assured to buy and use such products.

Manufacturers implement production and testing procedures in strict accordance with ISO 9001 quality management practices to ensure that all raw materials come from renewable sources and do not contain any harmful heavy metals or other contaminants. In addition, the finished product needs to be independently inspected by a third party before it can be put on the market. This means that consumers can fully trust the safety of this product and enjoy worry-free shopping.

Easy-to-use operation experience

Share tips and precautions on how to properly use TPU hot melt adhesive film. Guide the user to select the appropriate parameter settings according to different fabric types, and demonstrate the specific steps to ensure the best bonding effect. In addition, some common mistakes will be mentioned for reference to avoid risks.

In order to achieve the ideal state, please first determine the specific material properties (such as thickness, density, etc.) of the required treatment area. Then set the pressure value and time length of the iron or press recommend according to the instructions to prepare for preheating. Then place the cut film between two layers of fabric and gently press it until it is evenly distributed and completely covers the entire area. Finally, wait a little while for its natural cooling and hardening to successfully complete an efficient and reliable fixed operation process.

From design to finished product: the key link to improve the quality of clothing.

Describes how designers skillfully integrated TPU hot melt adhesive film into the design concept to create a new clothing line that combines fashion sense and practicality. Give examples of the advantages of several successful cases, such as the flat appearance of seamless splicing or the peace of mind brought by enhanced protection.

many well-known brands of garment production lines have begun to use such technical means in large quantities, because they found that compared with ordinary manual embroidery or lathe workers, using special pasting methods to draw patterns is not only less expensive and more efficient, but also more stable and reliable in finished product quality, which is not easy to fade and slag. More importantly, you can also express a variety of complex graphics textures and even three-dimensional effects without limitation.

Application scenarios that meet diverse needs

Several typical clothing application scenarios are listed to show the strong adaptability of TPU hot melt adhesive film. Including but not limited to windproof thermal jackets, breathable sweat-wicking sportswear, tear-resistant outdoor adventure suits, etc. In each case, there are specific needs, and that's where TPU comes in.