With the continuous improvement of consumers' requirements for clothing functionality and design sense, traditional sewing and bonding methods can no longer meet the needs of modern clothing manufacturing. At this time, a new type of material-TPU hot melt adhesive film is quietly leading the industry change.

What is TPU hot melt adhesive film and why it is popular

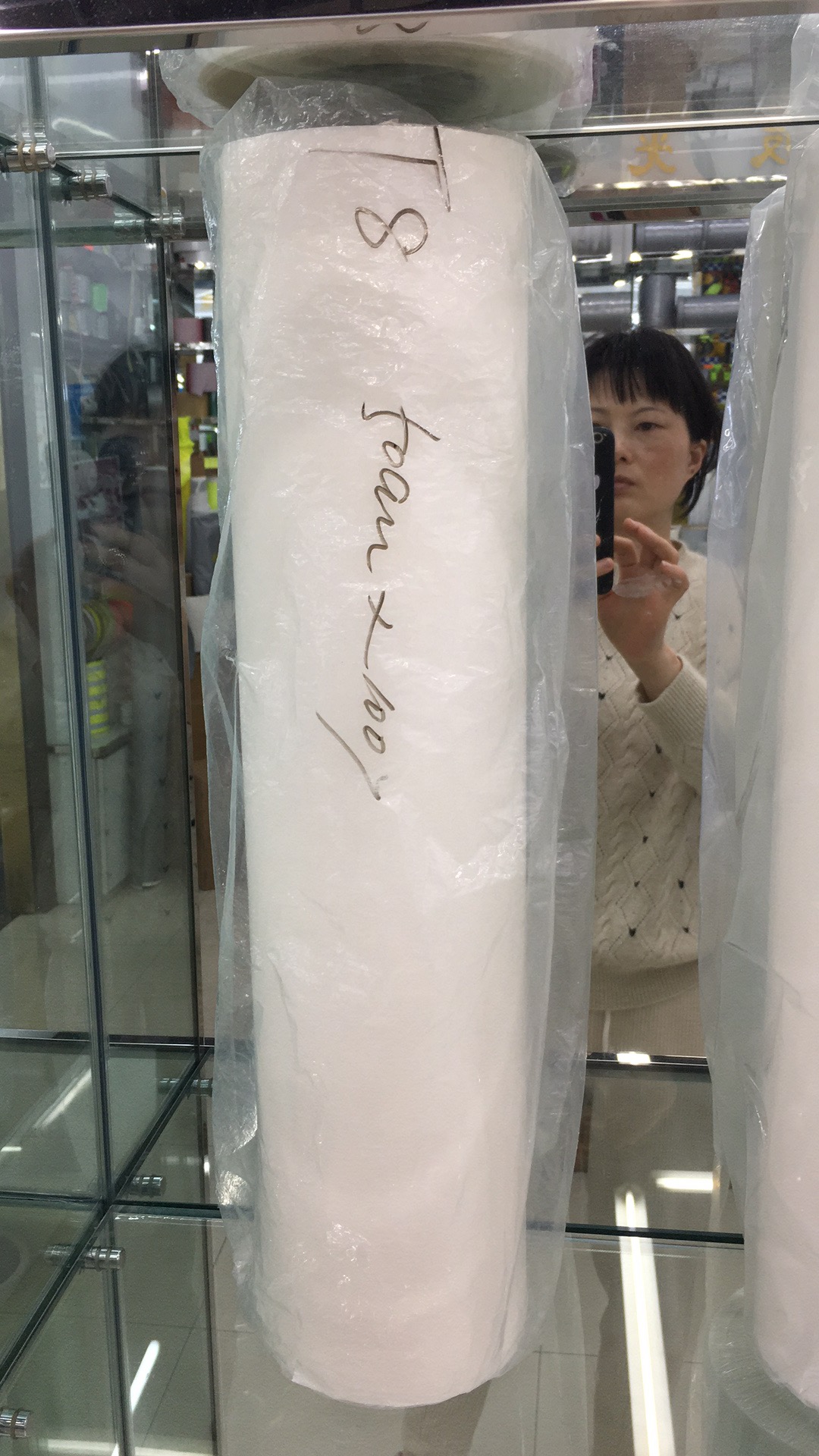

TPU hot melt adhesive film is a film-like material made of high molecular polymers with excellent flexibility and transparency. It can be activated by heat and tightly combined with a variety of substrates, thus replacing traditional needle and thread or chemical solvents for seamless connection.

Compared to other types of adhesives, TPU hot melt adhesive film is more environmentally friendly, durable and easy to handle. For example, in the field of sportswear, the product can effectively reduce the problem of cracking at traditional stitches caused by repeated washing, while giving the garment better elasticity and comfort.

Breaking the Bounds: Innovative Application of TPU Hot Melt Adhesive Film in Fashion Design

With its unique physical properties and technical advantages, TPU hot melt adhesive film is driving designers to challenge new heights. Whether it is a weatherproof jacket for outdoor adventure or a single item for urban commuting in pursuit of extreme lightness, this magic component can be used to achieve perfect presentation.

In addition, for those brands that require a large amount of embroidery printing decoration, the use of seamless stitching technology can significantly reduce the difficulty of post-processing, thereby shortening the overall delivery cycle.

Depth analysis: the core characteristics and technical principles of TPU hot melt adhesive film

the reason why TPU hot melt adhesive film can stand out in the highly competitive market environment is mainly due to the following key elements:

firstly, the quality stability is controlled from the source, and the difference between batches of each production is ensured to be minimized by accurately adjusting the formula proportion; The second is to customize and develop exclusive models for specific application scenarios, such as adding high temperature resistant coatings to adapt to the environment of high frequency welding equipment, etc; finally, the production process is continuously improved to achieve higher efficiency standards.

Environmental Protection and Sustainable Development: Reasons for Choosing TPU Hot Melt Adhesive Film

Under the background of advocating the concept of green and low-carbon on a global scale, more and more enterprises begin to pay attention to whether their supply chain is clean and friendly enough. In this regard, TPU hot melt adhesive film undoubtedly set a good example.

Compared with some competing products containing volatile organic compounds (VOC), this series of products are completely free of any harmful substances to human health and can be recycled throughout the life cycle. This allows customers who choose it not only to enjoy excellent technical performance, but also to fulfill their due social responsibility mission.

Successful Case Sharing: How Famous Brands Use TPU Hot Melt Adhesive Film to Enhance Competitiveness

An internationally renowned sports brand has faced such a problem-how to retain the original characteristics of the classic style charm, but also to meet the current trend of young people's preferences? After in-depth research and analysis, it was decided to introduce the latest generation of TPU hot melt adhesive film solutions.

This proved to be a wise move! It not only solves the long-standing problems that have plagued the R & D team for a long time (such as local ventilation hole blockage), but also unexpectedly gains unexpected results-that is, it greatly improves the overall fit of the whole piece of clothing when wearing, and wins the majority of consumers. The enthusiastic pursuit.

To sum up, we can clearly see that TPU hot melt adhesive film has become an indispensable part of today's clothing industry. Whether you're an up-and-coming entrepreneur or a veteran manufacturer, you should seriously consider incorporating this advanced technology into your production system.