In today's fast-growing fashion and functional apparel market, the choice of materials is crucial. Especially for products that need to be both beautiful and practical, a good adhesive can be the key to success or failure.

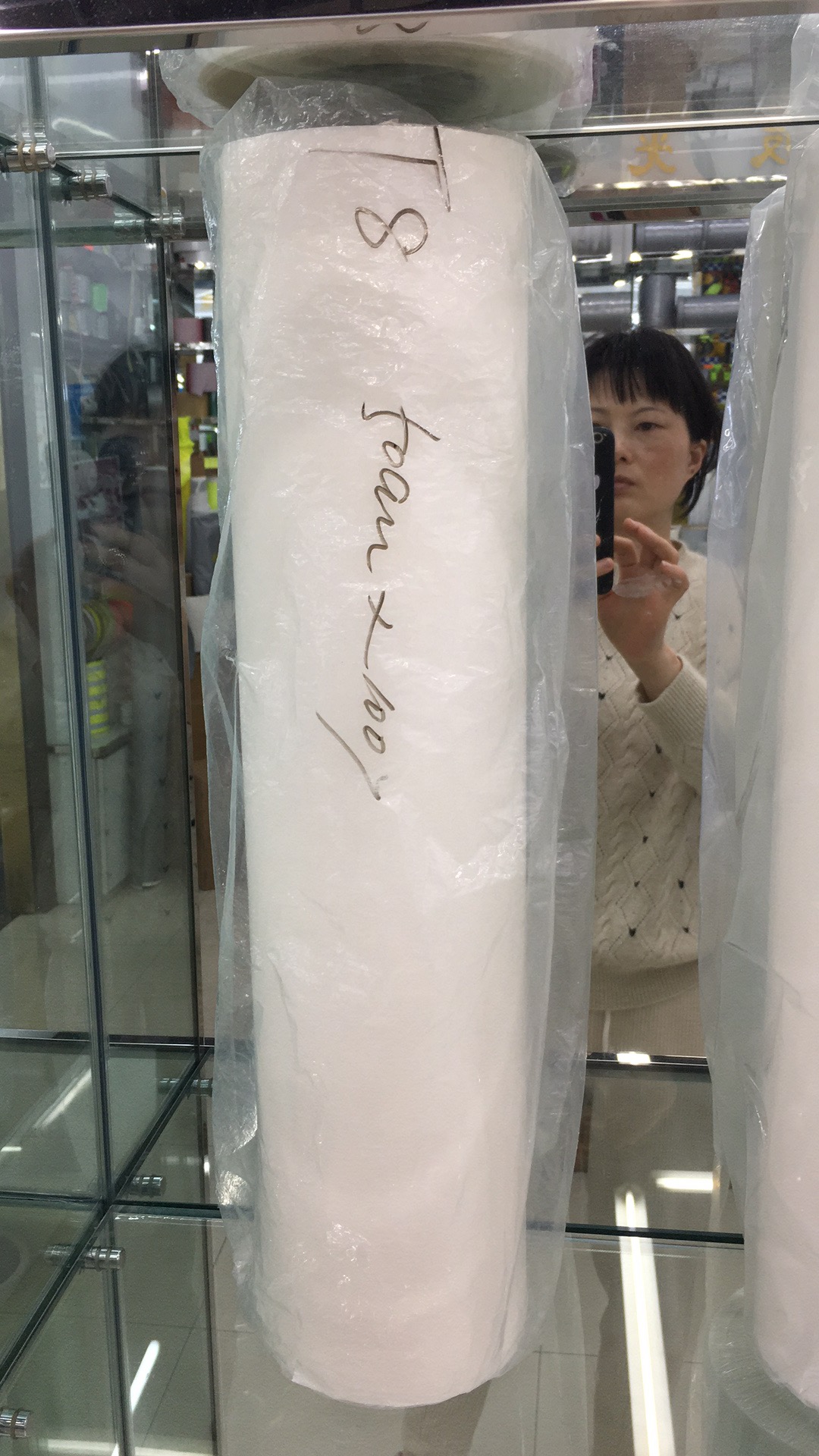

TPU hot melt adhesive film is an ideal choice that is widely used in modern garment industry. With its excellent physical and chemical properties and green environmental protection properties, it stands out among many similar competitors.

As a revolutionary technological achievement, this kind of film not only has the basic advantages of ordinary pressure-sensitive products-such as convenient operation and good cost-effectiveness, etc.; at the same time, it also has some unique advantages:

- -It is made of polyurethane elastomer, so there is no residual problem of toxic substances, and it meets the increasingly stringent international environmental protection standards;

- -Its mechanical strength is very high, even under extreme conditions can maintain a stable working state, such as high temperature ironing or low temperature freezing environment will not occur embrittlement phenomenon;

- -What's more worth mentioning is its super adhesion characteristics, which is suitable for almost all natural cellulose fabrics and synthetic polymer substrates to form a strong and lasting connection between the surfaces.

Compared with the traditional sewing stitch stitching method, the use of TPU hot melt adhesive film for composite lamination processing can significantly improve the overall appearance quality level of the finished product. Because the seamless transition area formed after the heating and pressurizing process is smoother and finer, and the distribution of possible pinhole water leakage risk points is completely eliminated. In addition, the overall production cost expenditure can be further reduced by reducing the amount of excess parts consumed.

At present, there are many successful cases on the market that prove the practical application value of this new material is very vast:

from the daily casual attire to professional athletes competition equipment are involved in covering the period. Especially in the production of raincoats, ski suits and other types of protective jackets, it is particularly important to show an irreplaceable role. It is also suitable for reinforcing the inner part of the shoe to extend the service life and so on.

Of course, if you want to obtain the ideal final effect expression, you must pay attention to adjusting the relevant parameter settings! Factors such as the size of the temperature control interval, the degree of the applied pressure value and the duration of the holding pressure will directly affect the results of the final quality evaluation standard ~ therefore, it is suggested that you can modify and optimize them flexibly according to your specific actual situation ~

with the continuous innovation and progress of science and technology, the pace of development is accelerating, the pace is intensifying, and the trend of obvious enhancement is becoming more and more obvious. I believe that in the near future, more and more advanced and higher-grade new models and styles will come out one after another for everyone to choose and purchase for trial experience! At that time, the entire textile industry will usher in another round of vigorous development. The arrival of the golden opportunity is just around the corner!