Breaking through tradition: the road to innovation of TPU hot melt adhesive film

In the past, traditional adhesives have many shortcomings in clothing manufacturing. For example, although some chemical solvent-based glue can provide strong adhesion in a short period of time, it is easy to age and fail over time, resulting in problems such as cracking and falling off of clothes. However, physical pressure-sensitive adhesive is difficult to cope with the challenges in humid environment and loses its effectiveness once it encounters moisture.

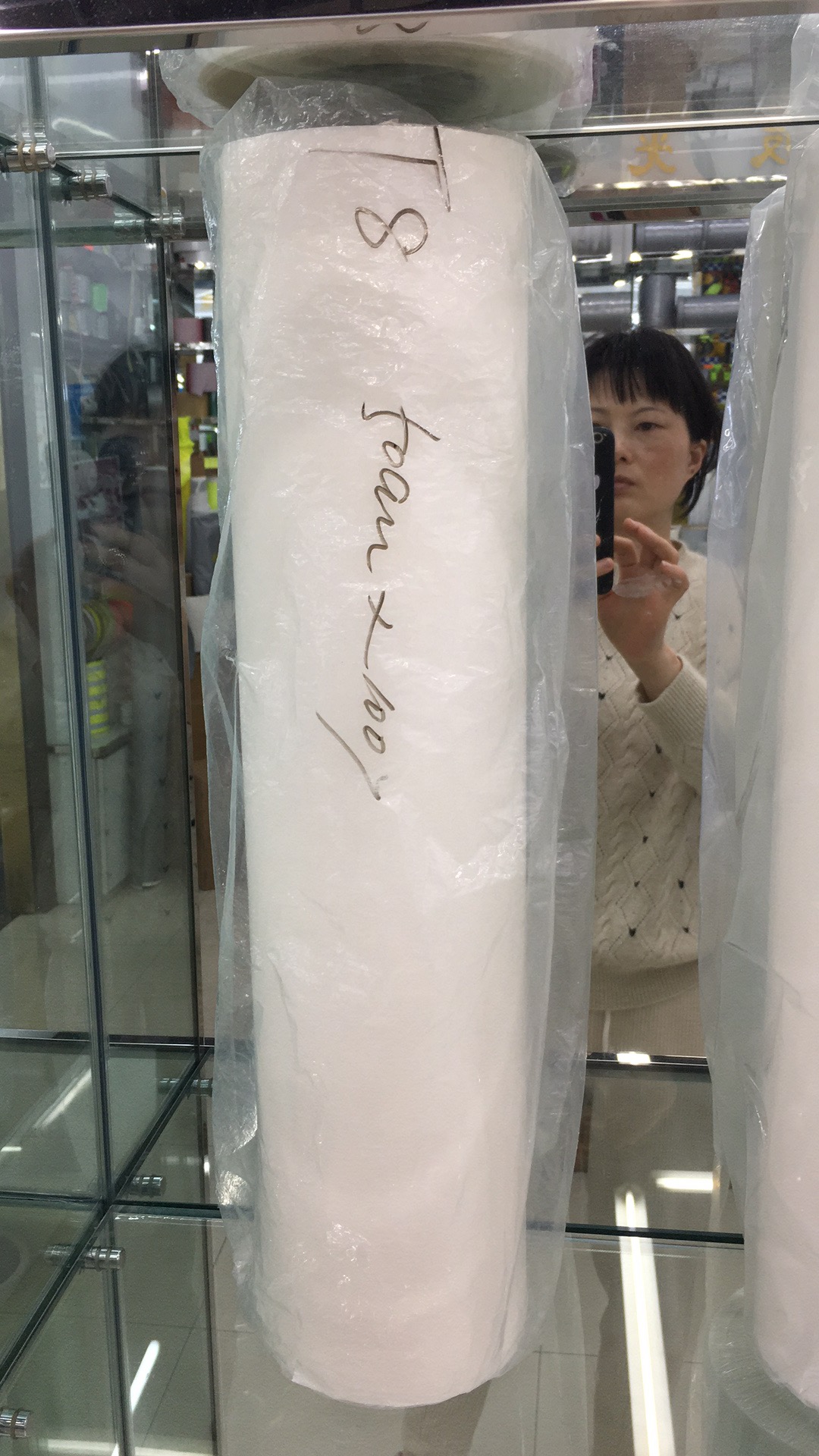

In contrast, TPU hot melt adhesive film with its unique physical and chemical properties completely changed the situation. It is a professional-grade double-sided adhesive film made of polyurethane, which has extremely high strength and excellent waterproof performance. Even under extreme conditions, it can maintain a stable bonding state for a long time, and can be easily disassembled and reattached as needed, which brings great convenience to production.

Multidimensional analysis: technical advantages of TPU hot melt adhesive film

In-depth understanding of TPU hot melt adhesive film is not difficult to find that the secret of its success lies in the outstanding performance of a number of key technical indicators. The first is the wide operating temperature range (-40°C to 80°C), which means that it can be used normally regardless of the severe cold and heat; the second is the unparalleled softness and elastic resilience-even after repeated stretching and compression No permanent deformation marks are left. Together, these features form an ideal platform to help garment manufacturers achieve higher efficiency and higher quality finished products.

Not only that, but when faced with complex structural design tasks (such as three-dimensional cutting or multi-layer stacking),TPU hot melt adhesive film also performs well. It can perfectly fit a variety of surface shapes and does not affect the subsequent process operation, providing more space for designers to play. Practical applications have shown that the use of this new material can greatly simplify the processing process, shorten the delivery cycle, and significantly improve the appearance and texture of the final product.

Green future: the development prospect of environmentally friendly TPU hot melt adhesive film

With the increasing awareness of environmental protection around the world, more and more companies are beginning to pay attention to the ecological impact of their operations. As an innovative textile accessory, TPU hot melt adhesive film has an advantage that cannot be ignored in this regard. The first is to follow strict environmental protection standards from the raw material selection stage to ensure that all ingredients do not contain harmful substances to the human body; the second is that the low volatile organic compound (VOC) emissions throughout the life cycle are much lower than the industry average, which helps Create a healthy and safe living environment.

Looking ahead, researchers are working to develop more energy-efficient production processes and product forms that are easy to recycle. For example, by improving the formula to make the product easier to decompose and recycle, or to convert the remaining waste into other useful resources for re-use. All of this will push the industry towards a more sustainable direction.

Flexible application: the perfect partner in diversified garment processing

Thanks to a wide range of functionality and adaptability, TPU hot melt adhesive films have been widely used in many market segments. Whether it is a functional coat in the field of sports casual wear, a high-strength protective piece required for outdoor adventure wear or a basic underwear necessary for daily wear, you can see the figure of this "invisible assistant. According to the characteristics of different fabrics and process requirements, the parameters are carefully allocated to set the scheme, and strive to achieve the most ideal effect.

it is worth mentioning that there are also some special customized versions for special purposes, such as models with windproof and breathable coatings that can give users all-round care in cold weather. Or is it a choice with good moisture absorption and perspiration effect suitable for wearing in high temperature environment in summer. In short, no matter how demanding the requirements can always find the right solution.

Quality assurance: excellent performance supported by strict quality control system

Behind each piece of TPU hot melt adhesive film is the hard work of a high-quality team. From the initial selection of raw materials to the final shipment of the goods will go through numerous rigorous and meticulous quality inspection procedures. Through the implementation of full tracking management of key nodes, the possibility of non-conforming products entering the market is minimized.

record and save the experimental data in a scientific and reasonable way, and regularly update and maintain the database folder, so that every query can be based on rules. In addition, well-known experts and scholars at home and abroad are often invited to participate in exchange seminars to share valuable experiences and lessons, and continuously improve the overall technical level and service capabilities. The certification issued by many authoritative organizations fully proves the reliability and trustworthiness of the brand.

Success Story: Customer Witness Achievement Value

Since its inception, many well-known brands have chosen TPU hot melt adhesive film as one of the partners, and have achieved remarkable results. At first, a famous international sports brand just tried a small number of samples for new product testing projects with the attitude of giving it a try. Unexpectedly, once it was launched, it was warmly sought after by the majority of consumers. Subsequently, the two sides decided to expand the scale of cooperation and gradually established a solid strategic alliance for more than a decade.

Another person in charge of the company interviewed said: "Since the switch to this new material, it is obvious that the product quality has made a qualitative leap." Not only is the feel more delicate and smooth, but also the durability is greatly improved. "The most important thing is that the after-sales service provided by the supplier is very considerate and timely to solve the problem. The attitude is sincere and responsible." It can be seen that it is with excellent strength and considerate service that it has won unanimous praise from inside and outside the industry.