In the textile industry, which is constantly pursuing high quality and durability, TPU hot melt adhesive film, as a high-performance double-sided adhesive, is gradually subverting the traditional bonding method. Suitable for a variety of substrates, providing excellent waterproof performance and durable connection, especially suitable for outdoor sports equipment and high-end clothing manufacturing. This paper will discuss the technical advantages of TPU hot melt adhesive film and its wide application in modern garment industry.

The moment of innovation: the birth of TPU hot melt adhesive film

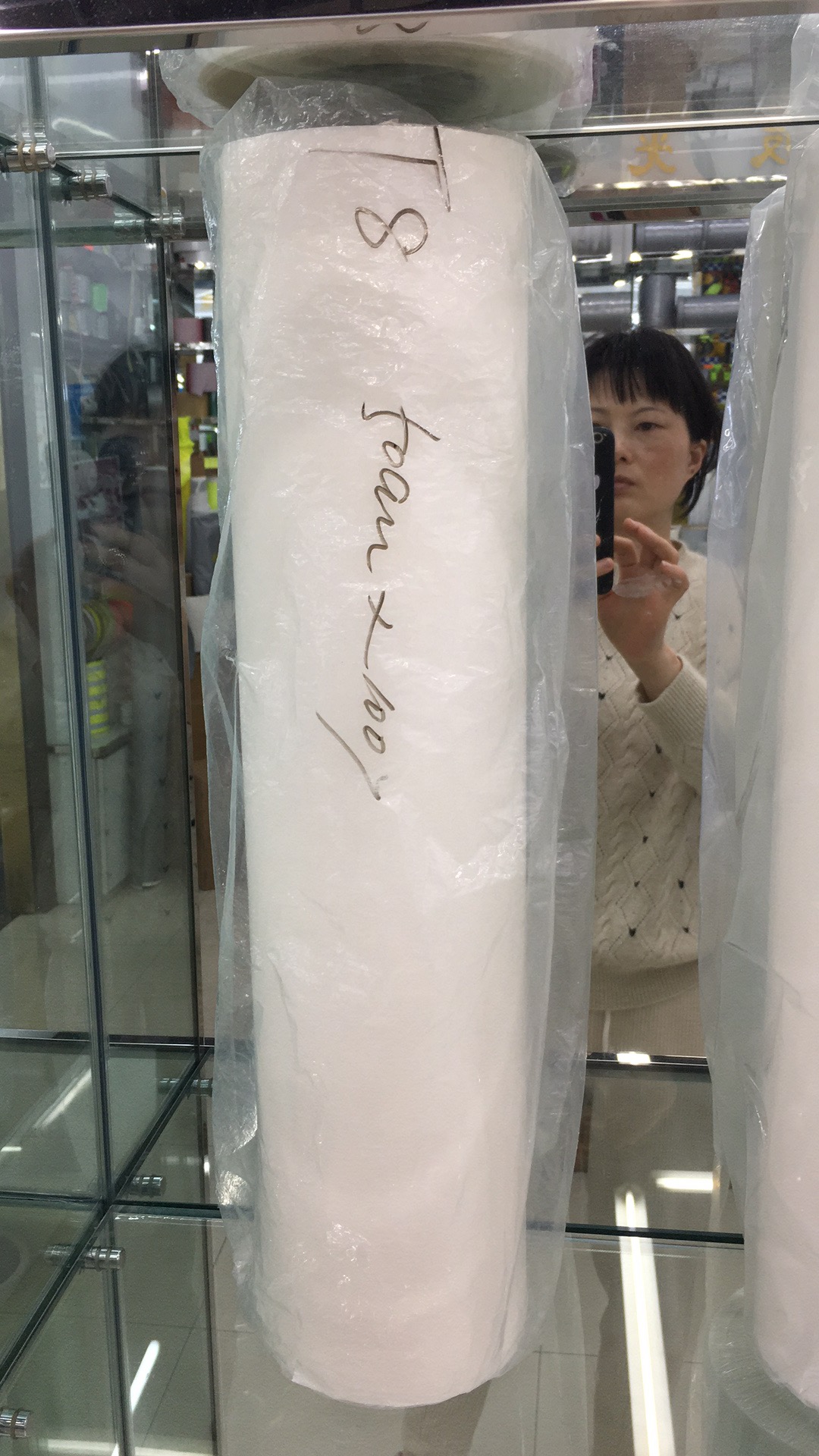

In the face of the urgent market demand for both functionality and comfort, the textile industry is in urgent need of innovative bonding solutions. At this critical moment, TPU hot melt adhesive film, a thermoplastic polyurethane film carefully developed by Artiz, was born. With its superior physical properties and environmental characteristics, TPU hot melt adhesive film has become a star product in the industry, leading the technological revolution in the textile field.

Core competitiveness: unique advantages of TPU hot melt adhesive film

TPU hot melt adhesive film is not just an adhesive, it is a leap in materials science. It has excellent waterproof and breathability, even in extreme environments, can maintain a stable adhesion, not easy to moisture or degradation. Its unique elasticity and extensibility make the clothing still maintain its original shape and size after long-term wearing, which meets the pursuit of modern people's lasting beauty of clothing. More importantly, the TPU hot melt adhesive film hardly produces harmful substances during the curing process, which is in line with the concept of green production and is favored by consumers with strong environmental awareness.

Industry Focus: Application Field Expansion of TPU Hot Melt Adhesive Film

The application range of TPU hot melt adhesive film is far beyond people's imagination. In outdoor sports equipment, it is used for seamless splicing to ensure the integrity and waterproof performance of clothing, so that explorers are not afraid of wind and rain. In the production of high-end women's clothing, TPU hot melt adhesive film because of its high transparency and uniform thickness, can achieve complex structural bonding, does not affect the overall look and feel of clothing, but also to enhance the durability of clothing. Even in the field of smart wearable devices, TPU hot melt adhesive film, with its fine bonding ability, helps to achieve the precise combination between electronic components and fabrics, and promotes the progress of wearable technology.

Example Analysis: Application Case of TPU Hot Melt Adhesive Film of Famous Brand

The North Face, a world-renowned outdoor brand, fully uses Artiz TPU hot melt adhesive film to reinforce the suture area in its latest assault clothing series, which significantly improves the waterproof performance and tear strength of the product and has won high praise from the market. In addition, the famous designer brand Chanel uses TPU hot melt adhesive film to fix the details in its advanced customization series, which not only enhances the artistic expression of the clothing, but also ensures that every show is wonderful and flawless.

Looking to the future: the development prospect of TPU hot melt adhesive film

With the increasing global emphasis on sustainable development and the continuous promotion of scientific and technological innovation, TPU hot melt adhesive film will usher in a broader market opportunity. Artiz promises to continue to invest research resources to further optimize the performance indicators of TPU hot melt adhesive films and explore more application scenarios, such as antibacterial, UV protection and other functional treatments, to meet diversified and personalized product needs. We believe that the future textile industry will become more colorful, greener and smarter because of the popularity of TPU hot melt adhesive film.