Understanding TPU Hot Melt Adhesive Film

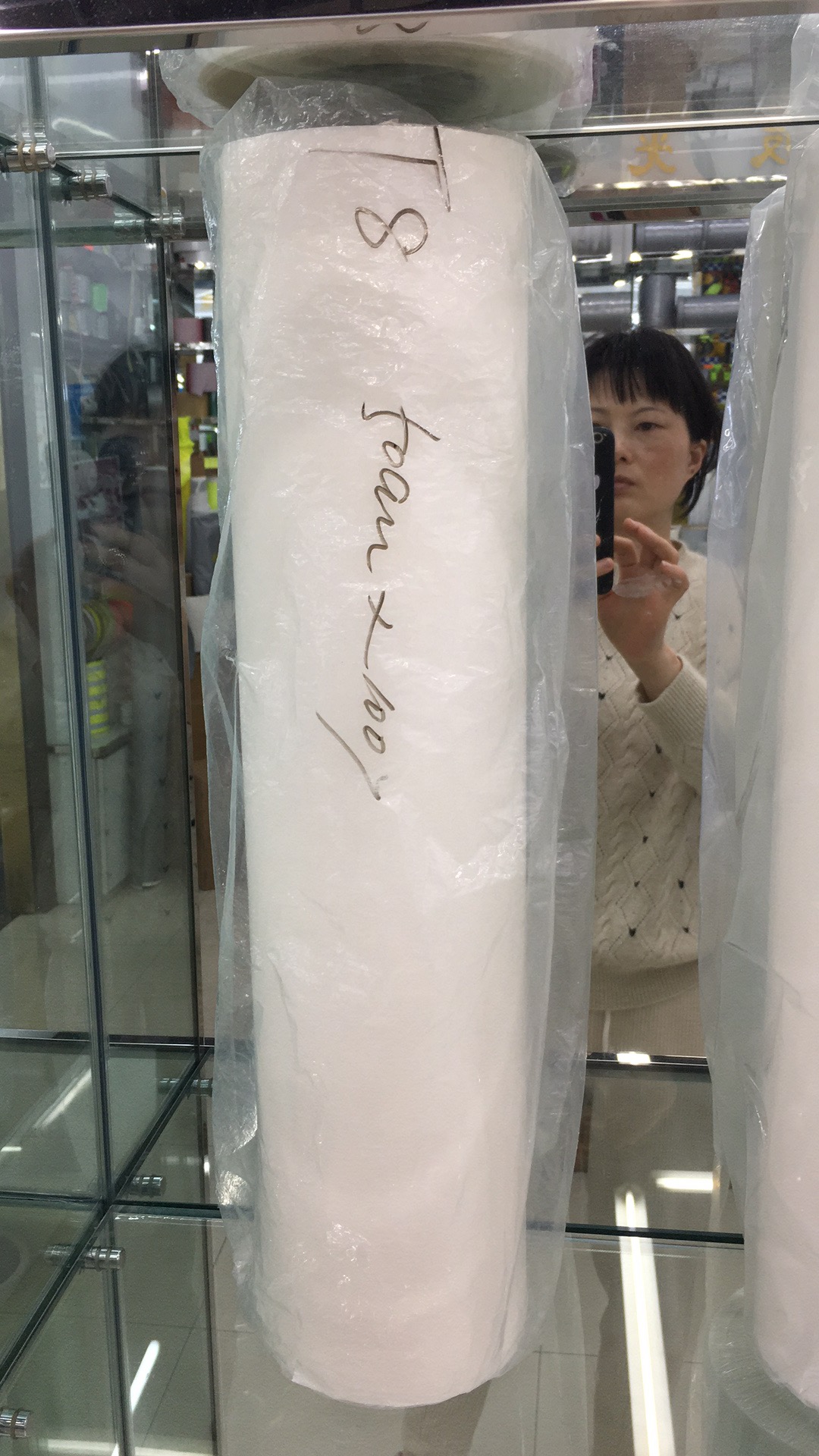

What is TPU Hot Melt Adhesive Film?

TPU (Thermoplastic Polyurethane) hot melt adhesive film is a versatile bonding material used extensively in the garment industry. Composed of thermoplastic polyurethane, this adhesive film provides excellent bonding strength, flexibility, and durability. Unlike traditional adhesives, TPU hot melt adhesive film is applied using heat, which activates its bonding properties, ensuring a strong and lasting bond between fabrics.

In comparison to traditional adhesives, TPU hot melt adhesive film offers several key characteristics such as superior bonding strength, resistance to wear and tear, and the ability to maintain fabric softness and pliability.

Historical Context

The evolution of adhesive technologies in the garment industry has been marked by significant advancements. Initially, traditional adhesives were the norm, but they often failed to provide the durability and flexibility required for modern fabrics. The introduction of TPU hot melt adhesive film marked a significant milestone, offering a superior alternative that meets the rigorous demands of today’s garment manufacturing processes.

Advantages in Garment Manufacturing

Superior Bonding Strength

One of the most significant advantages of TPU hot melt adhesive film is its superior bonding strength. This ensures that bonded fabrics remain intact even under stress and movement, enhancing the durability of garments. Industry experts have praised this technology for its ability to withstand wear and tear better than traditional adhesives.

Flexibility and Stretchability

TPU hot melt adhesive film maintains fabric softness and pliability, making it ideal for garments that require flexibility and stretchability. This is particularly important in sportswear and activewear, where performance under stress and movement is crucial.

Ease of Use in Production

The use of TPU hot melt adhesive film simplifies the bonding process, making it compatible with various fabrics. This compatibility reduces production time and costs, making it a cost-effective solution for garment manufacturers.

Impact on Product Quality

Improved Aesthetic and Functional Quality

Garments bonded with TPU hot melt adhesive film benefit from seamless finishes and clean lines, enhancing both the aesthetic and functional quality. This results in garments that are not only visually appealing but also comfortable for end-users. Numerous brands have adopted this technology, showcasing its benefits through various case studies.

Environmental and Safety Benefits

TPU hot melt adhesive film is non-toxic and eco-friendly, complying with industry safety standards. Its use contributes to sustainable garment production, making it a responsible choice for manufacturers looking to minimize their environmental impact.

Applications Across the Garment Industry

Diverse Use Cases

TPU hot melt adhesive film is used in a variety of garments, including casual wear, formal wear, and outerwear. It is also employed in the production of accessories and footwear, highlighting its versatility.

Customization and Innovation

This adhesive technology enables bespoke designs and custom fits, offering potential for innovative garment features and functionalities. Manufacturers can leverage TPU hot melt adhesive film to create unique, high-quality products.

Challenges and Considerations

Technical Challenges

While TPU hot melt adhesive film offers numerous benefits, there are technical challenges to overcome. Initial implementation may require adjustments to ensure optimal adhesion on various fabrics. However, these challenges can be addressed through proper training and equipment.

Cost Implications

Manufacturers may face initial investment costs when adopting TPU hot melt adhesive film. However, the long-term savings in production time and improved product quality often outweigh these initial expenses. A cost-benefit analysis can help determine the feasibility for both small and large-scale manufacturers.

Future Trends and Developments

Technological Advancements

The future of TPU hot melt adhesive film is promising, with emerging innovations in adhesive technology. Integration with smart textiles and wearable technology is on the horizon, offering exciting possibilities for the garment industry.

Market Growth and Opportunities

The market for TPU hot melt adhesive film is expanding, presenting opportunities for new applications and business models. Manufacturers can explore these opportunities to stay ahead in the competitive garment industry.

Practical Tips for Manufacturers

Best Practices for Implementation

Integrating TPU hot melt adhesive film into production requires a step-by-step approach. Manufacturers should follow best practices, such as proper training and equipment setup, to ensure successful implementation. Common mistakes, such as inadequate heat application, should be avoided.

Selecting the Right TPU Adhesive Film

Choosing the right TPU adhesive film involves considering factors such as fabric type and desired bonding strength. Industry experts recommend evaluating product specifications and conducting tests to select the best adhesive film for specific needs.

Expert Insights and Resources

Interviews with Industry Leaders

Insights from garment manufacturers who have adopted TPU hot melt adhesive film reveal its benefits and future potential. Industry leaders predict continued growth and innovation in garment adhesives.

Additional Resources

Manufacturers can access guides, tutorials, and workshops for further learning about TPU hot melt adhesive film. Research papers and industry reports provide in-depth information on the latest developments and trends.